PRODUCTS

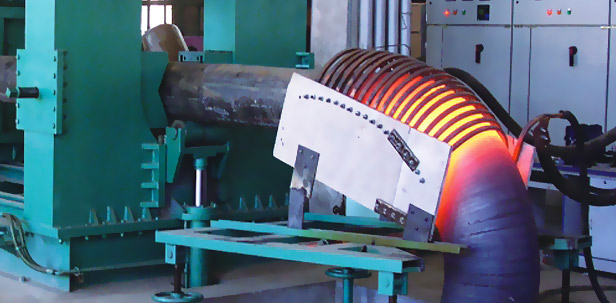

The company can produce: elbows, elbows, tees, reducers, flanges, corrugated compensators, sleeve compensators, non-metal compensators, rubber soft joints, expansion joints, insulation joints, support hangers, resistant Grinding pipe fittings, anti-corrosion pipe fittings, insulation pipe fittings and other products.

Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

45° Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

90° Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

180° Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

Short Radius Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

Carbon Steel Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

Stainless Steel Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

Galvanized Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

316 Stainless Steel Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

Sanitary Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

Alloy Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

High Pressure Elbow

The inner and outer surfaces of the elbow should be smooth, without detrimental strength and appearance defects, such as scars, scratches, heavy leather, etc., after the defects are found, they should be ground and the thickness of the ground should not be less than 93.5% of the original wall thickness. The ground should be smooth and the defects should be cleared with colorant or magnetic particle inspection.

Previous page

1

Next page

- TEL- +86-15226756063

- EMAIL- czlsg@163.com

- ADD- Yanta Road Industrial Area, Yanshan,Hebei.