|

Main processing technology

|

Raw materials enter the factory → unloading → heating → simmering → heat treatment → machining groove → surface treatment → finished product inspection → label protection → stocking

(Note: For stainless steel products, there is a pickling passivation process before surface treatment)

|

|

Specification model

|

DN15-DN3000 bending radius R≥2.5D

|

|

Material |

Carbon steel, alloy steel, stainless steel, aluminum, etc. Other customized production according to customer standard requirements |

|

Standard

|

National standard, American standard, German standard, Japanese standard and other customized production according to customer standard requirements

|

|

Wall thickness |

SCH5-STD-SCHXXS and other customized production according to customer standard requirements |

|

Color |

Black, yellow, blue, red and other customized production according to customer standards

|

|

Surface coating |

Anti-rust oil; black; galvanized; polyethylene coating; epoxy coating and other customized production according to customer standards |

|

Mark |

Steel stamping, spraying and other customized production according to customer standard requirements |

|

Certificate |

ISO9001-2015 EU CE etc. |

|

Brand |

Longsheng Pipeline |

|

Minimum purchase quantity |

1piece |

|

Payment terms |

Wire transfer, acceptance, online banking remittance, cash, etc. |

|

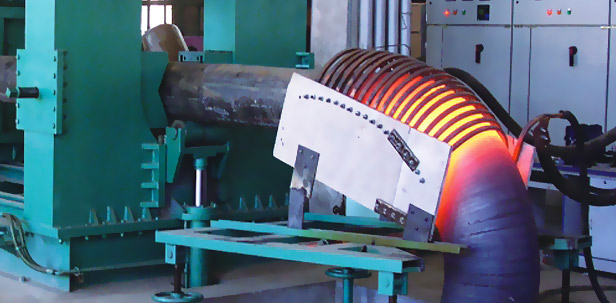

Main equipment and installation

|

1: 1 hydraulic pushing machine (same as seamless pushing elbow equipment)

2: Lead screw mechanical pushing machine 1 set (same as seamless pushing elbow equipment)

3: 1 intermediate frequency heating equipment (same as seamless push elbow equipment)

4: 1 intermediate frequency heating equipment (same as seamless push elbow equipment)

5: Machining equipment: power head lathe JT250 TX50 TX63AF

6: Heat treatment furnace: 1 trolley type fuel oil heat treatment furnace, effective heating area of 8m2, trolley type box-type resistance furnace RT9-80*1500*60, maximum furnace temperature 1200℃

7: Inductor: (for material heating) 40 sets

8: 8 sets of rotating rocker tooling

9: One air compressor (for air cooling of hot simmering alloy steel elbows)

10: Two sets of sandblasting equipment (same as seamless push elbow equipment)

11: Two plasma cutting machines

|

一、Acceptance of raw materials

1、Raw materials should meet the requirements of the relevant standards or technical specifications.

2, the surface of raw materials should be free of oil, too much rust corrosion and obvious dent defects,low melting point metal pollution.

3, inspection of raw materials quality certificate, furnace number,Lot number,specifications, manufacturers and implementation standards.

4, raw materials with wire brush for mechanical rust, so as to meet the requirements of nondestructive testing.

5, the size of the raw material testing (length, width, thickness and steel pipe unevenness).

6, into the factory after the steel pipe and steel plate, should be ultrasonic re-examination,grade I is qualified.

7, physical and chemical testing,into the plant of steel and steel according to the furnace batch number,specifications pumping chemical element analysis,mechanical properties, hardness test, the test results should meet the requirements of raw material standards.

8, after re-inspection according to the factory rules Number Registration.

二.Manufacturing process

① Material selection cutting, elbow to select the appropriate steel or steel pipe,with a template scribing with oxygen alkyne flame or sawing machine cutting,and the raw material furnace, batch number and pipe specifications, Project Name, Number identification clearly.

② The steel plate rolling, welding.

③ With a crane to the desired mandrel into the push machine, the blank is further cleaned, the inner wall coated with graphite, and then mounted on the push rod (according to the length of the blank can be installed more than one time), the mandrel with flapper locking, preheating the inner mold to the appropriate temperature push system (heating temperature and propulsion speed should be the best fit).

④ Adjust the intermediate frequency heating coil, the tube is heated to the required temperature, control the propulsion speed.

Buckle buckle Bend, The Shape of the elbow with a suitable tire in the hydraulic machine to correct the radius of curvature.

⑥ To the end, according to the specifications of the elbow with the appropriate tire alignment on the beveling machine, and then the cutting gun is fixed, cut off the excess blank, and leave processing margin to the car.

⑦Integer, with a special tire clamping elbow, with a support head on the press port integer.

4.Heat treatment: according to the heat treatment process, the elbow into the furnace heat treatment.

5.Surface treatment: pipe fittings after heat treatment with sandblasting machine to remove the surface scale.

6.After the surface treatment of the elbow Weld 100% ray detection,Grade II qualified.

7.Mechanical properties testing: according to the relevant standards, the mechanical properties of the elbow test, to ensure that the mechanical properties of the elbow standards, testing items and sampling orientation should meet the requirements of the relevant standards.

8.End processing: according to the design to confirm the drawings for mechanical end face processing Bevel.Within the range of 50mm from the end of the tube, inside and outside the Weld more than high angle grinder grinding.

9.Appearance detection

① Elbow shall not have cracks and other phenomena, the surface should be no hard points.

② Any defects on the elbow tube body is not allowed to be repaired by welding.

10.Size testing: by the company's relevant testing personnel, according to the drawings and pipe fittings related standards for size testing, and to meet the tolerance requirements.

11.Surface treatment: elbow inside and outside the surface should be smooth, no damaging strength and appearance defects,such as scarring, scratches, heavy skin, etc., found defects should be grinding treatment, grinding at the thinning amount is not less than 93.5% of the original wall thickness, grinding should be smooth and with a colorant or magnetic powder flaw detection to confirm the defect removal so far.

12.Nondestructive testing of elbows

After the elbow heat treatment, the company holds the relevant qualification certificate personnel,according to the standard requirements of the elbow magnetic powder, ultrasonic, test results reached Level I qualified.

13.Logo

Mark with a template airbrush or low stress stamp, the outer wall in order to clearly indicate the content of the standard requirements.

14.Stacking and transportation of elbows

Elbow during transport during transport can not be in contact with any part of the car, to avoid bumps.