Sleeve compensator

Product description

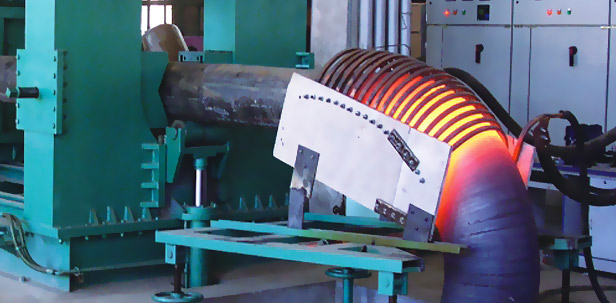

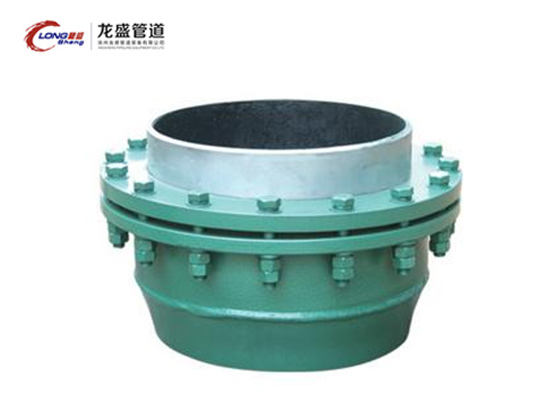

The sleeve compensator is called a tube expansion joint. It is a compensation device for hot fluid pipelines. It is mainly used to absorb and compensate the axial thermal expansion displacement that occurs after the auxiliary installation of the linear pipeline. It is a kind of direct installation in any non-corrosive one-way or multiple Compensator in the pipeline to the fluid. Sleeve-type compensator. It is widely used in pipelines for urban heating, metallurgy, mining, power generation, petrochemical, construction and other industries. It is mainly composed of sleeve (core tube), shell, sealing material, etc.

Structural features

It is mainly composed of sleeve (core tube), shell, sealing material, etc. It is used to compensate the axial expansion of the pipeline and the axial rotation at any angle. It has the characteristics of small volume and large compensation, suitable for hot water, steam, grease and other media , Through the sliding movement of the sliding sleeve to the outer sleeve, the thermal expansion is compensated.

The inner sleeve of the sleeve-type compensator is connected to the pipeline, and adopts the principle and structure of high-performance self-pressure dynamic sealing. It can slide freely in the shell with the expansion and contraction of the pipeline, which can adapt to the sealing requirements of any pipeline. The inner sleeve is sealed with a new type of synthetic material, which can withstand high temperature, anti-corrosion and anti-aging. The applicable temperature is -40 to 150, and can reach 350 under special circumstances. It can not only ensure axial sliding, but also ensure that the medium in the tube does not leak.

The sleeve-type compensator is designed with an anti-breaking device, which can ensure that it will not be pulled apart when it stretches to the limit position, so that the safety of the entire pipeline network is greatly improved.

Sleeve type compensator is suitable for medium engineering pressure ≤2.5MPa, medium temperature -40℃~600℃.

The sleeve type compensator uses a new type of sealing material, flexible graphite ring, which has the characteristics of high strength, low friction coefficient (0.04~0.10), no aging, good effect, and convenient maintenance.

The sleeve-type compensator has a long service life, and the fatigue life is equivalent to that of the pipeline. The sliding surface is specially treated, and it has good corrosion resistance in salt water, salt solution and other environments, which is more than 50 times higher than austenitic stainless steel. At the same time, when the sealing effect is weakened due to wear after many years, the flange can be tightened again to enhance the sealing performance, or the bolt can be loosened, the pressure ring can be removed, and one or two layers of sealing ring can be installed to compress the pressure ring. ,continue to use.

The sleeve type compensator has no requirement on the chloride ion content, and is especially suitable for systems where the medium or the surrounding environment exceeds the chloride ion standard.

The direct-buried sleeve type compensator can be directly buried in the ground, and there is no need to set up a maintenance well during installation, and the project cost is low.

Types of

The sleeve type compensator is divided into one-way type and two-way type compensation structure. The feature of the two-way type is that no matter where the medium flows in from the compensator, the sliding sleeves at both ends of the compensator always slide freely to achieve two-way compensation and increase the amount of compensation. .

Common product series

ZHTTB-B series elastic sleeve compensator

ZHZTB-B series direct buried sleeve compensator

ZHN-H-I series thrustless sleeve compensator

ZHN-H-II Series DC Thrustless Sleeve Compensator

ZHYTB-A series disposable sleeve compensator

ZHSLT series double flow direction sleeve compensator

installation method

General sleeve

1. The sleeve-type compensator should be properly kept during installation to prevent the sun, rain and dust pollution.

2. During installation, check whether the compensator's model specifications are consistent with the design, and the product surface should be free from bumps, pits, severe corrosion and other defects that affect product quality.

3. When the total length of the finished product of the disposable compensator is consistent with the sample, it is not necessary to stretch or compress. If the installation marking on the telescopic main pipe changes, it should be adjusted before installation

4. For the two-way non-thrust compensator, it must be installed in the flow direction of the medium indicated in the diagram. When the medium is steam, it will avoid the formation of air locks in the compensator. In order to ensure equal compensation in two directions of the compensator, the two-way compensator must be arranged in the middle of two fixed points during design.

5. The pipe section welded to both ends of the compensator must be broken, and the water pressure test shall be carried out as required after welding (the bolts at both ends of the packing chamber should be tightened until there is no leakage). After running for 24 hours, the bolts at both ends of the packing chamber must be tightened again.

6. In order to ensure that the pipeline has no lateral displacement, it only telescopes in the axial direction, and a guide bracket is installed on the side of the telescopic tube. When the two guillotines of the compensator have axial displacement, guide brackets should be installed on both sides to ensure that the axial displacement does not exceed one degree of the eccentricity (+-) of the compensator.

7. The thermal insulation and waterproof structure of the compensator can be the same as that of the pipeline, but it can't restrict the expansion section.

8. Special circumstances will be discussed separately.

New sleeve type

1. When installing the compensator, first check whether its specifications are consistent with the order.

2. The sliding sleeve of the one-way compensator should be installed at the inflow end of the medium.

3. The pipe section welded between the new sleeve type compensator and the two ends of the compensator must be grooved. After welding, the water pressure test should be carried out according to the acceptance specification, and the pressure is 1.5 times the working pressure. If the sealing device leaks during pressure test, the bolts should be evenly tightened until there is no leakage.

4. The compensator is installed along the center line of the pipeline, with different axis degrees greater than 1% to prevent excessive friction during operation and affect sealing.

5. A guiding sliding support should be installed at the pipeline close to the compensator to prevent lateral displacement.

6. Pay attention to protect the sliding surface, and it is strictly prohibited to bruise or corrode.

7. The outer sleeve of the two-way compensator should be held up by a fixed support and kept concentric with the pipeline. The compensation distance on both sides should be approximately the same.

8. The compensator can be installed at the maximum length under various temperatures, without pre-tensioning or pre-compression (the maximum length of the product is the maximum length when leaving the factory).

Advantages of sleeve compensator

1. The sleeve compensator has a long service life, and the fatigue life is equivalent to that of the pipeline. The sliding surface is specially treated, and it has good corrosion resistance in salt water, salt solution and other environments, which is more than 50 times higher than austenitic stainless steel. At the same time, when the sealing effect is weakened due to wear after many years, the flange can be tightened again to enhance the sealing performance, or the bolt can be loosened, the pressure ring can be removed, and one or two layers of sealing ring can be installed to compress the pressure ring. ,continue to use.

2. The sleeve compensator has no requirement on the chloride ion content, and is especially suitable for the system where the medium or the surrounding environment exceeds the chloride ion standard.

3. The sleeve compensator is divided into one-way type and two-way type compensation structure. The feature of the two-way type is that no matter where the medium flows from the compensator, the sliding sleeves at both ends of the compensator always slide freely to achieve two-way compensation and increase compensation. the amount.

4. The direct-buried sleeve compensator can be directly buried in the ground, and there is no need to set up a maintenance well during installation, so the project cost is low.

Previous

None

- TEL- +86-15226756063

- EMAIL- czlsg@163.com

- ADD- Yanta Road Industrial Area, Yanshan,Hebei.